To obtain these details, you can refer to the company’s employment records that has a list of all the employees and their hourly rates. total manufacturing cost formula Here’s a short video explaining how the cost of goods sold formula works in manufacturing. One other staff member – a specialist coffee roaster – earns $35 per hour, with payroll taxes of $5 per hour and $3 fringe benefit costs per hour. Richard has two staff members who earn $25 per hour, their payroll taxes costs $5 per hour and they have $3 worth of fringe benefit costs per hour.

- Unlike direct labor and materials, overhead costs are not directly tied to each product but still contribute to the overall cost.

- Plus, if your material prices or labor costs change frequently, you might want to check them more often.

- Unless you keep track of manufacturing costs, there’s no way to know if you hit the revenue targets or suffer a loss following a production period.

- As employees use Clockify to clock in and out, employers gain insights into the total number of hours each employee worked on each production line.

- When you’re running a complicated manufacturing operation with many moving parts, again, efficiency is key.

- The finance head refers to indirect overhead cost, which shall be incurred irrespective of whether the product is manufactured.

What To Know About Batch Production: A Product Seller’s Guide

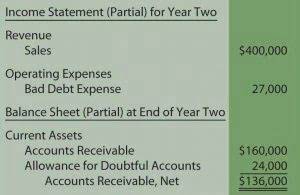

For instance, a clothing manufacturer can determine whether a specific line of clothing is profitable by comparing its production costs to the revenue generated. The direct material cost should never be calculated by multiplying the number of final products with the material quantities from their contra asset account BOMs. Work in process inventory, waste, and scrap all need to be accounted for as well. This is why raw material inventory and material purchases should only be used to calculate direct material costs. Once you identify the indirect costs, get detailed expense data for each of these overhead cost categories for a specific period, such as a month or a year.

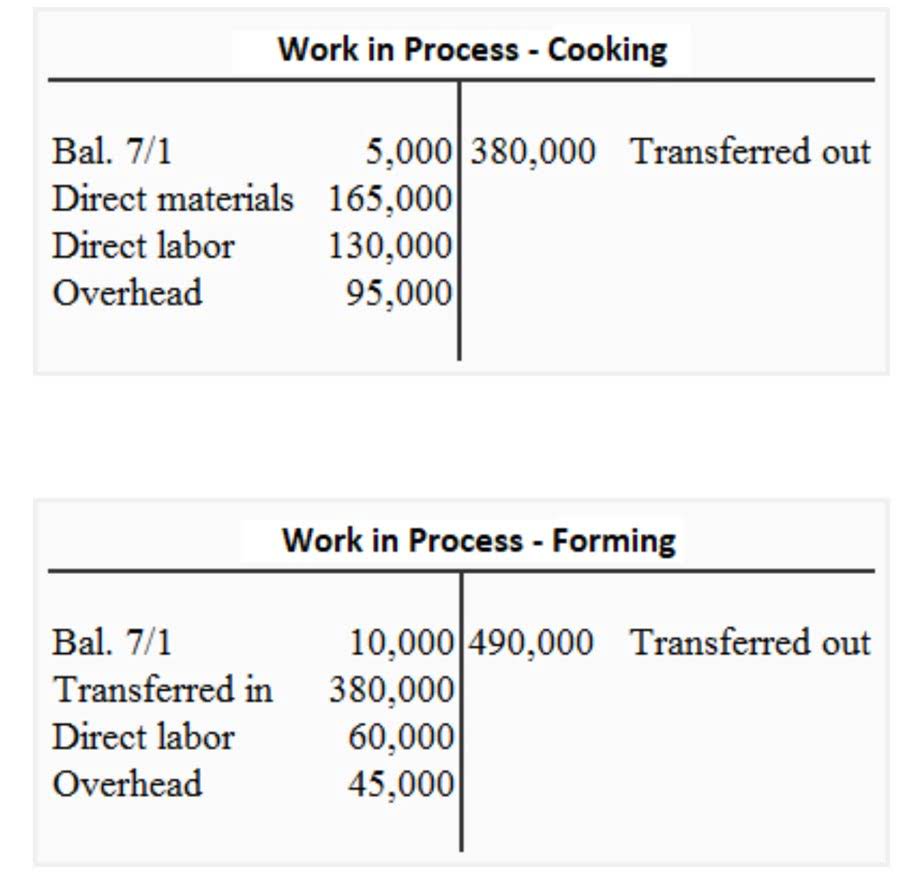

Manage your supply costs

The total manufacturing cost https://www.bookstime.com/ formula is a simple equation in which all of these are added together. Total manufacturing cost is a financial metric that expresses the total amount of funds spent on all production activities during a financial period. In plain terms, it is the total cost a company spends on manufacturing its products. As such, calculating TMC precisely is invaluable for anyone looking to gain more insight into their manufacturing cost accounting fundamentals. “When a manufacturer begins the production process, the costs incurred to create the products are initially recorded as assets in the form of WIP inventory.

How can businesses reduce Total Manufacturing costs without compromising quality?

However, in cases where all materials are used, the COGM and total manufacturing cost would be the same. Direct costs change based on the production period and how much product you manufacture. This generally includes materials and labor, which vary based on many factors, such as demand planning and staffing.Wondering how to calculate direct materials cost? Direct materials are calculated by subtracting the direct materials left at the end of the production period from the total amount of materials you started with and purchased in the period. The total manufacturing cost formula can be one of the most critical metrics for manufacturing businesses or those with a manufacturing and production management component. This calculation provides insight into how much it costs to make your product, identifying any underlying inefficiencies or exorbitant expenses.

© Accounting Professor 2023. All rights reserved

In either case, understanding product costs is essential for making informed pricing decisions. Detailed product costing is important for informed decision-making around pricing in manufacturing. Product costs are used to calculate the selling price, impacting profitability. Understanding all the factors that contribute to the cost of a product helps managers make better decisions about pricing and other strategic initiatives.

- As you produce more, your machinery’s wear and tear intensify, requiring increased maintenance and potentially additional repairs.

- You can even set reminders for timesheets to make sure that everything runs smoothly.

- By using the total manufacturing cost formula, companies can make informed decisions about cost-cutting strategies and pricing models.

- In periodic inventory systems, where things are done manually or using spreadsheets, regular stocktakes need to be performed and material invoices summed up to get the numbers right.

- In our comprehensive exploration of total manufacturing cost, we have discovered the valuable insights it provides for maximizing profitability.

To calculate direct labor costs, add up what you pay in salaries, benefits, retirement funds, holiday pay, payroll taxes, workers compensation insurance, etc. for both your fixed-labor and variable-labor employees. A manufacturing overhead budget covers all fixed, variable and applied manufacturing overhead costs of an organization. These costs are then allocated to each unit that’s produced and documented as part of the cost of goods sold in a manufacturer’s master budget. You can also use the formula below to calculate a predetermined manufacturing overhead cost rate that will be allocated to all the units that are produced instead of allocating overhead costs to each of them. If you’d like to know the overhead cost per unit, divide the total manufacturing overhead cost by the number of units you manufacture.

Leave a Reply